Grafting Robot

The grafting robot is a high-precision automated system designed to perform grafting tasks. This robotic system handles the entire grafting process, from cutting to joining rootstocks and scions, improving efficiency and quality. The robot is designed to work with a variety of scion and rootstock combinations to yield high-quality grafts.

Quick grafting in 10-18 seconds

Compatible with sizes up to 25 mm

Precision with 3D scanning

Separation of non-graft materials

Built for summer and winter grafting

Real-time and remote troubleshooting

Durable components

Optimal cutting

HOW IT WORKS

Preparation

Pre-cut roots and scions are placed in the system.

3D Material Scanning

The robot accurately scans the dimensions of the rootstock and scion.

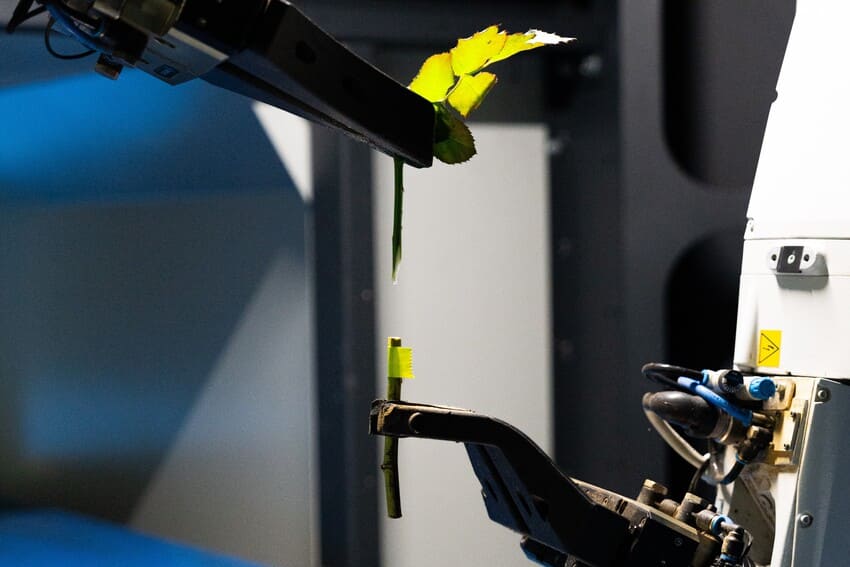

Automatic Cutting

It calculates the optimal cutting length and cuts the rootstock and the scion.

Assembling

The robot aligns and grafts them by applying appropriate pressure.

Output

The completed graft is placed onto a conveyor belt for easy collection and further processing.

Grafting Robot is a Smart Investment

Save Time and Increase Output

Automate grafting to handle more plants in less time with fewer people.

Ensure Consistent Quality

Achieve precise, uniform grafts for better plant health and higher quality.

Reduce Labor Costs

Minimize reliance on skilled labor while maintaining high productivity.

Meet Seasonal Demands

Scale easily to meet both peak and off-season demands without compromising quality.

Long-Term Savings

Reduce labor costs and errors, making it a smart investment that pays off quickly.

Revolutionizing the Art of Grafting with Precision and Efficiency

How It Works: Step-by-Step Process

Preparation: Rootstocks and scions are pre-cut to size and delivered to the machine.

Operator Input: A single operator feeds the rootstock and scion into the machine.

3D Scanning: The robot scans dimensions, curvature, and deviations of the materials.

Cutting and Matching: Based on the scan, the robot calculates the optimal cut for precise cambium alignment.

Assembling: The rootstock is banded, and the scion is inserted with the correct pressure for maximum stability.

Output: The completed graft is placed onto a conveyor belt for easy collection and further processing.

Why Choose the Grafting Robot?

Flexible & Versatile: Easily handles a wide range of scion and rootstock combinations without requiring exact diameter matching.

Cost-Effective: Operated by a single person, the robot significantly reduces labor costs while increasing output.

Year-Round Grafting: Suitable for both summer and winter grafting.

Enhanced Quality Control: Delivers consistent, high-quality grafts, improving plant health and nursery yield.

Service Excellence

Remote Support: Real-time assistance ensures smooth operation.

Durability: High-quality components for reliable, long-term performance.

Continuous Innovation: Designed to grow with your nursery’s needs.

Invest in the future of your nursery with the Grafting Robot by Horti Robotics. Achieve precise, high-quality grafts, reduce labor, and scale your operations with ease.

Precision Grafting:

Grafting cycle time: 10-18 seconds per graft, depending on material quality and product thickness.

Suitable for bare-root, P9 pots, and stem grafting.

Flexible scion and rootstock diameter combinations:

Rootstock: 5–25 mm

Scion: 4–20 mm

Handles scions as small as 4 mm grafted onto rootstocks as large as 20 mm, ensuring exceptional versatility.

Maximum product length: 120 cm, measured from root base or pot to the tip of the scion..

Advanced Automation:

3D Scanning: Analyzes rootstock and scion dimensions for precise cambium matching.

Optimal Cutting Calculations: Automatically calculates cutting length for stable and secure grafts.

Variable Pressure Application: Adjusts insertion pressure based on scion and rootstock thickness.

Auto Recovery & Collision Detection: Reduces downtime by handling potential issues seamlessly.

Non-Viable Product Handling: Automatically separates non-graftable materials.

Built for Reliability:

Durable, high-quality components ensure long-lasting performance.

Remote Support: Real-time troubleshooting through remote login capabilities.

Minimized Downtime: Engineered for maximum reliability and operational efficiency.

FAQs

How long will it take for my team to get accustomed to using the grafting robot?

What type of maintenance does the grafting robot require?

What happens if the robot malfunctions during operation?

Can the grafting robot handle grafting on plants with irregular shapes or sizes?

Can I use the grafting robot for small-scale nurseries, or is it designed for large operations only?

How does the grafting robot improve graft success rates?

Will the grafting robot help speed up production during peak seasons?

Does the robot work with different grafting techniques or only standard methods?

Can I adjust the robot’s settings for different plant species or growing conditions?

How does the Grafting Robot handle grafting during seasonal changes (extreme temperatures)?

© 2025 by Horti Robotics | Gerealiseerd door NIKU Solutions